Battery recycling process holds promise for sustainability improvement

Leadership Insights newsletter story

Battery recycling process holds promise for sustainability improvement

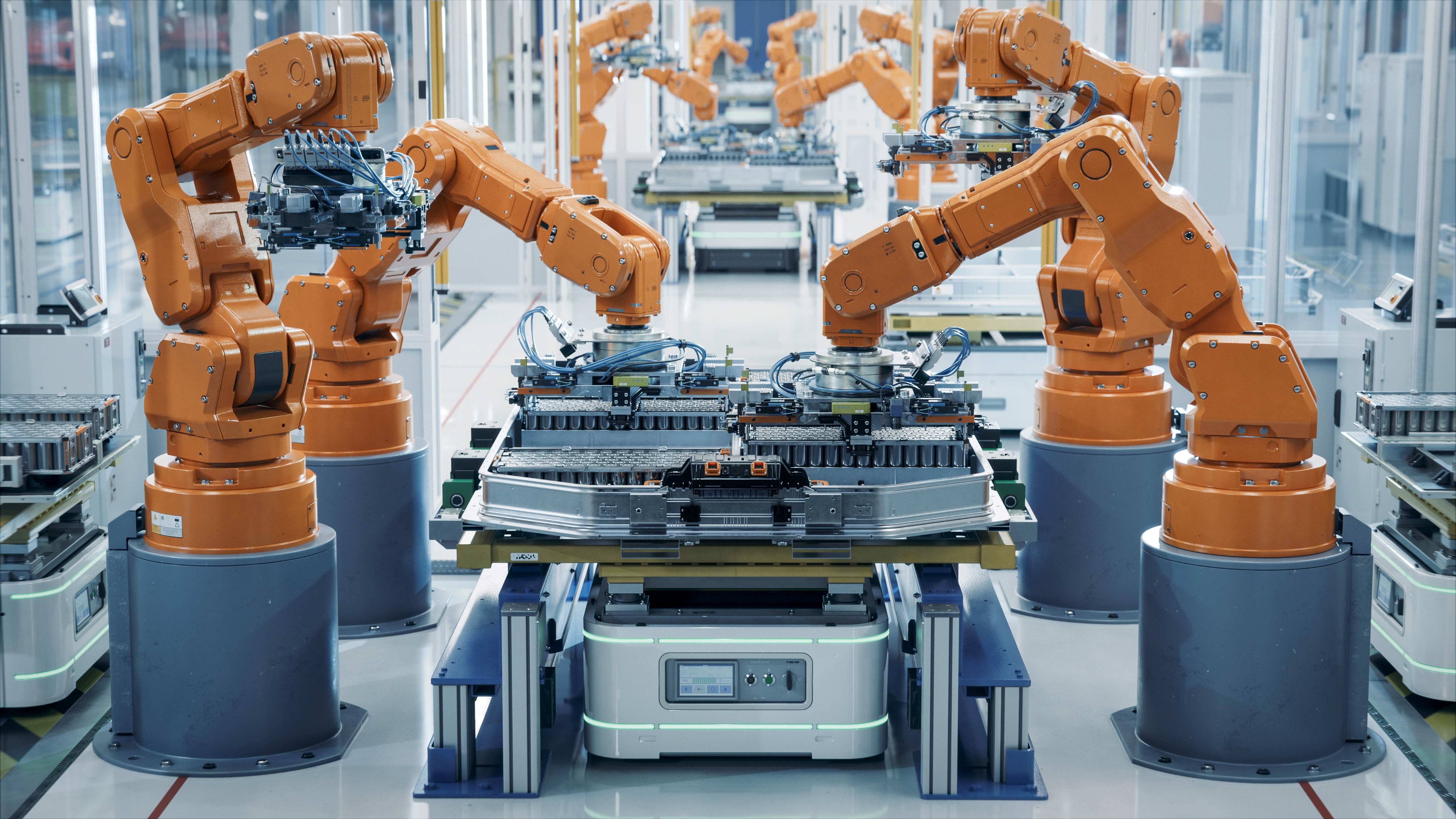

A new method for the recovery of lithium and aluminum from lithium-ion batteries holds the potential to increase the sustainability credentials of battery powered vessels.

Researchers at Sweden’s Chalmers University of Technology have developed a process which uses oxalic acid, an organic compound found in fruits and vegetables, including spinach and rhubarb, to recover 98% of the lithium and 100% of the aluminum from ground up lithium-ion battery “black mass”.

Research leader Martina Petranikova told ICS Leadership Insights that the process does not affect the recovery of other materials in the black mass like cobalt, manganese and nickel.

The advancement could lead to improvements in battery sustainability by easing demand for the mining of metals like lithium and cobalt. Depending on the extraction method, the environmental concerns around lithium mining include very high-water use, water and air pollution, and emissions related to the energy requirements of lithium processing.

“By 2050, recycled batteries could provide a substantial portion of the key minerals needed to electrify the shipping industry, reintroducing end-of-life batteries and their components into the economic cycle,” Panos Koutsourakis, ABS Vice President, Global Sustainability, told ICS Leadership Insights.

The extraction levels of the oxalic acid recycling process compare favourably to the industry standard method of dissolving black mass in inorganic acids like sulphuric and nitric acid with the addition of hydrogen peroxide, reactions which release various gaseous emissions and create waste streams and wastewater.

Research leader Martina Petranikova told ICS Leadership Insights that while it is too early to determine the overall energy requirements of the separation and recovery processes, the consumption of chemicals and production of secondary waste is lower using the new process.

The ability to scale up the process will be key to any future industrial adoption. A partial upscaling of the process maintained extraction efficiency, said Petranikova, a positive sign for its industrial potential.

Koutsourakis said that hybrid and battery power appeal to shipowners because of their lower CO2 emissions, flexibility to adopt renewable energy sources, and regulatory compliance benefits.

While there are few fully electric vessels in the world fleet and the energy density limitations of current battery technology limit their use in ocean shipping, batteries are a relevant and important technology for coastal vessels, ferries and a diverse range of hybrid electric ships.

The Chalmers team is continuing its research with a focus on the removal of copper and production of transition metals to make new cathode materials, Petranikova said.

Related content

Evaluating China’s decade of electrification

Technology for €88M hydrogen-fuelled steel plant holds promise for maritime innovations

Sharing information on battery safety